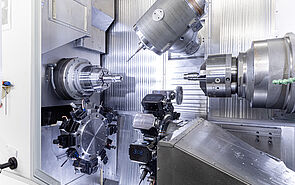

With Acceptable Tolerances Now in the Range of a Hundredth of a Millimeter, the Production of Electronic Connectors Requires the Highest Precision

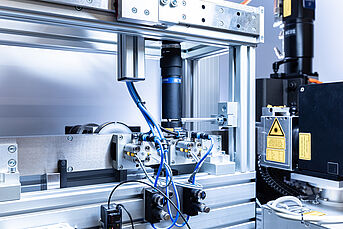

The Rosenberger Group meets these increased requirements with its high-quality stamping technology. Competence and experience guarantees reliable pluggability as well as highly resilient, stamped and formed (SF) connectors; especially under demanding conditions such as those found in the automotive industry. Rosenberger quality is assured by the adoption of fully automated processes with 100% repeatability. Maximum efficiency is achieved by the integration of the latest cable assemblies during the initial design phase of all SF connectors.