In 2017 a new production building for surface coating - the single most expensive investment in the company's history - was put into operation. With the construction of this new electroplating shop a number of new facilities as well as safety precautions have been installed, all of which of course meet the European standards of the best available technology.

Because environmentally harmful chemicals are used during the electroplating process, along with plant requiring approval, the new building falls under the Federal Immission Control Act (BImSchG). The approval procedure is particularly demanding as all potential environmental effects must be evaluated.

The safety precautions include a fire alarm system with smoke detectors in the ventilation systems. In addition, the surface technology is protected against accidents on several levels with the derivation and interception of liquids escaping from electroplating baths being a top priority.

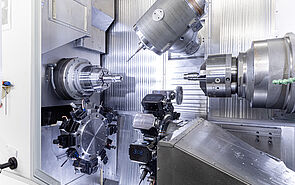

Due to the production process a large proportion of the metals used ends up as oil-contaminated chips in the chip and oil treatment plants. The cleaned oil can be pumped back into the cooling system and the metal chips - now containing less than two percent oil - to be returned to the materials supplier almost sorted by type.

This ensures optimal recycling of materials and only small quantities of new raw materials needing to be purchased.

A special feature is the highly efficient biomass heating plant. Around one sixth of the total energy required is generated by the heating plant using renewable energy sources - in this case local wood chips.

Rosenberger can cover more than 98% of its heating needs through the biomass heating plant. To meet the same energy demand with oil fuel about 565,000 liters would be necessary. Rosenberger’s initiative therefore translates into an emission saving of approx. 1,500 tons of CO2.

The new Energy Center is equipped with four air compressor and heat recovery systems.

Since 2008 about 4,200 MWh of heat energy has been recovered. Accordingly, more than 1,000 tons of CO2 have been saved.

To further increase the efficiency of our heat recovery the waste heat from the compressed air generation is used as process heat for our surface technology. In this way, the amount of heat energy recovered can be increased to approx. 1.5 GWh per year which enables savings of over 2,000 m³ of wood chips per year.

In 2022 Rosenberger installed further photovoltaic systems at the Fridolfing site. As a result, the site now has approx.. 4,600 PV modules on a roof area of 7,800 m. The system supplies the company with approx. 1,700,000 kWh of solar electricity per year, thus saving almost 715 tons of CO2 per year. At the same time emissions such as lead, nitrogen oxide or mercury are reduced.

A special feature of the photovoltaic system is the zero feed-in. By using 100% of the electricity produced by the solar plant, Rosenberger does not feed into the public Grid, therefore waiving the state feed-in tariff.