Rosenberger products stand for precision, durability and quality at the highest level. The company has considerable expertise in the automotive sector from two decades of designing and producing both customized solutions and standard products.

High-tech companies rely on the precision and reliability of Rosenberger’s high quality products. The Rosenberger group invests strategically in the development of new high-quality products, in the most advanced manufacturing and business processes, in resource conservation and environmental protection.

Rosenberger products stand for precision, durability and quality at the highest level. The company has considerable expertise in the automotive sector from two decades of designing and producing both customized solutions and standard products.

The future with 5G connections for fast, secure and efficient data exchange

The Rosenberger Group, as a development partner in the field of industrial measurement technology, designs and manufactures high-quality precision products for use in various measurement technology applications.

Rosenberger is an experienced connection solutions partner to customers in the Industrial sectors. With a global presence, the company provides a comprehensive portfolio of innovative, high quality connection products backed by extensive professional services.

Rosenberger’s proven solutions competence ensures the delivery of reliable, innovative, high precision connectors for use in medical hardware and software components.

DIN EN 9100, ESCC and MIL-PRF 39012 qualified components.

Intelligent business processes in the industrial sector require professional end-to-end solutions. Rosenberger serves the entire process chain with sophisticated hardware and software while also providing associated services for the respective business environments.

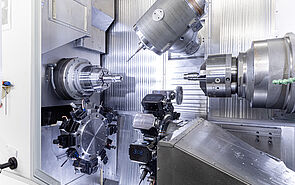

The company’s custom machining capability is highly impressive, providing maximum flexibility and resilience in terms of capacity utilization and logistics. In addition to extensive problem-solving, the Rosenberger Group offers production processes that are tailored to specific customer requirements.

As a renowned manufacturer, the name Rosenberger is associated with the most advanced technology, quality and creativity. The Rosenberger Group provides a wide range of standardized and customized connectivity solutions in high-frequency and fiber optic technologies.

Rosenberger designs and manufactures connectors that are engineered to reliably transmit data and power in numerous types of applications with various requirements.

Regardless of whether standard or custom assembly, Rosenberger develops and manufactures fit-for-purpose cable assemblies for signal-, data- and power transmission.

To fulfill the highest demands of R&D, test labs, or quality assurance departments, Rosenberger offers a comprehensive range of high-precision RF test & measurement products.

The demand for high-speed data transmission in global mobile networks continues to grow rapidly. The choice of connectivity products or solutions between the BBU/PSU, RRH and antenna is an essential key element to achieve the best network performance.

Rosenberger offers a wide range of specialist tools and accessories including those for crimping and handling crimp inserts, as well as torque wrenches and various extraction tools and accessories.

Rosenberger provides customized solutions – cost-optimized and timely – from the initial idea right through to volume production.

Download catalogs, flyers and other latest product information as well as measurement data protocols for your products.

Read the latest news from Rosenberger and check out our trade fair appearances. If you want to receive the latest news by email, register for our newsletter.

We have the pragmatic power of innovation that is needed to keep tackling new challenges and developing solutions that help our customers move forward.

A Tittmoning fitters workshop turns into a worldwide concern that is technically one of the most innovative as well as one of the largest and most reputable in its sector.

More than 15,000 employees work for the Rosenberger Group worldwide every day - 3,300 of them at our headquarters in Fridolfing. With their commitment and competence they are responsible for the success and the future of the company. You too can become an indispensable part of our team!

In our job portal you will find all current vacancies for the Rosenberg headquarters in Fridolfing, Germany.

Our connectivity experts will be happy to give you further information on our solutions. Get in contact with us to find the best connection solution for your application.

Ever higher packing densities and steadily increasing signal speeds for semiconductor components make it increasingly difficult to contact devices under test (DUT) with the required signal integrity. Traditional spring contact pins - produced using classic manufacturing methods - cannot be minimized to the required extent.

Therefore Rosenberger uses the so-called LIGA process (lithography, electroplating, molding): using methods from semiconductor production, very small and equally complex mechanisms are produced. The MCI contact pin manufactured using the LIGA process offers structural elements in a size range of 10 μm; the mechanical and electrical properties are optimized due to the special geometry of the contact pin. With the LIGA process, Rosenberger is currently producing, for example, a range of test probes explicitly for microwave wafers and PCB test systems.

This patented technology ensures high-precision measurements with low contact resistance and excellent impedance control. There is only transmission of the high-frequency microwave signal to the coplanar contact structure within the shielded, air-insulated probe body. This maintains signal integrity at constant power in a temperature range from 10 K to 300 °C.

Contacting the test object with Rosenberger test probes is uncomplicated, reproducible and requires significantly reduced overtravel than before. This is due to the robust design of the coplanar contact structure and the omission of the micro-coax cable in the test tip.

Features of the Rosenberger test probes:

MCI contact elements are manufactured in an electroforming process. They meet the highest precision requirements with a small form factor due to the metal being built up in an additive process. With this procedure Rosenberger is able to reproduce parts on a microscale with a depth of detail down to 3 µm.

The additive process enables the development of extremely small and precisely defined shapes that can be produced with repeat accuracy. The precisely defined geometry forms the basis of a compact and reliable design: tailor-made for the individual application using Rosenberger Group’s many years of experience and competence in the development and manufacture of micro components. Innovative tools for design, simulation and verification are used throughout the company's own production facilities.

Classic application examples of these manufactured parts are interposer or board-to-board connections.

What distinguishes Rosenberger products?