Because Reliability and Long-Term Partnerships Count: The Rosenberger Group Combines Competence and Experience at the Highest Level

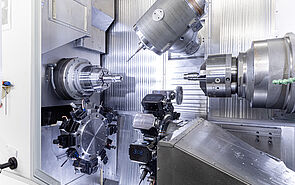

When Rosenberger was founded in 1958 the company’s core business was the machining of metal parts. Subsequently, Rosenberger entered the field of high-frequency technology and moved to its current headquarters in Fridolfing. Today, the Rosenberger Group is present worldwide, offering more than 60 years of specialist know-how, technological experience, and methodological competence.