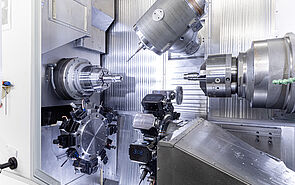

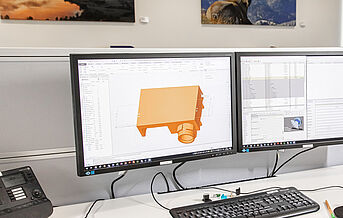

The Design and Construction of Rosenberger Products Involves the Selection of Materials, the Creation of Standard Parts and the Definition of Manufacturing and Assembly Techniques

It also includes the consideration of cost aspects as well as technical and design requirements.

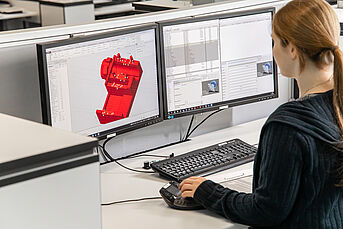

Product development takes place at Rosenberger in Fridolfing, however the synergies between different business areas are always optimized. 80 to 90 percent of designed parts represent customer-specific solutions that are rapidly transferred to series production after development. This is a key reason for Rosenberger’s world market leadership in the production of connectors for the automotive sector.

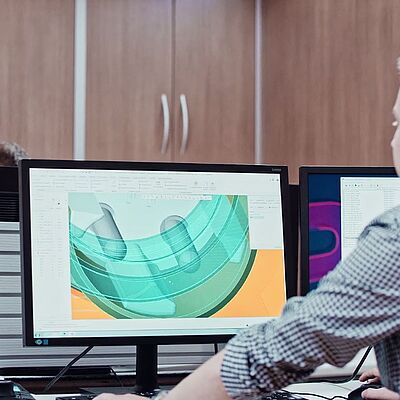

In the future areas such as simultaneous engineering and systematic development will become even more important. Simultaneous engineering requires the competence to view development processes from different perspectives. Therefore, in addition to the purely technical function the requirements of other organizational units such as production, assembly, logistics, purchasing and sales are equally taken into account. This achieves maximum efficiency in terms of implementation.