Rosenberger products stand for precision, durability and quality at the highest level. The company has considerable expertise in the automotive sector from two decades of designing and producing both customized solutions and standard products.

High-tech companies rely on the precision and reliability of Rosenberger’s high quality products. The Rosenberger group invests strategically in the development of new high-quality products, in the most advanced manufacturing and business processes, in resource conservation and environmental protection.

Rosenberger products stand for precision, durability and quality at the highest level. The company has considerable expertise in the automotive sector from two decades of designing and producing both customized solutions and standard products.

The future with 5G connections for fast, secure and efficient data exchange

The Rosenberger Group, as a development partner in the field of industrial measurement technology, designs and manufactures high-quality precision products for use in various measurement technology applications.

Rosenberger is an experienced connection solutions partner to customers in the Industrial sectors. With a global presence, the company provides a comprehensive portfolio of innovative, high quality connection products backed by extensive professional services.

Rosenberger’s proven solutions competence ensures the delivery of reliable, innovative, high precision connectors for use in medical hardware and software components.

DIN EN 9100, ESCC and MIL-PRF 39012 qualified components.

Intelligent business processes in the industrial sector require professional end-to-end solutions. Rosenberger serves the entire process chain with sophisticated hardware and software while also providing associated services for the respective business environments.

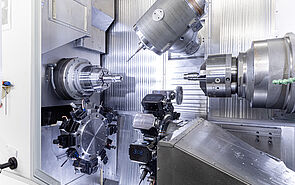

The company’s custom machining capability is highly impressive, providing maximum flexibility and resilience in terms of capacity utilization and logistics. In addition to extensive problem-solving, the Rosenberger Group offers production processes that are tailored to specific customer requirements.

As a renowned manufacturer, the name Rosenberger is associated with the most advanced technology, quality and creativity. The Rosenberger Group provides a wide range of standardized and customized connectivity solutions in high-frequency and fiber optic technologies.

Rosenberger designs and manufactures connectors that are engineered to reliably transmit data and power in numerous types of applications with various requirements.

Regardless of whether standard or custom assembly, Rosenberger develops and manufactures fit-for-purpose cable assemblies for signal-, data- and power transmission.

To fulfill the highest demands of R&D, test labs, or quality assurance departments, Rosenberger offers a comprehensive range of high-precision RF test & measurement products.

The demand for high-speed data transmission in global mobile networks continues to grow rapidly. The choice of connectivity products or solutions between the BBU/PSU, RRH and antenna is an essential key element to achieve the best network performance.

Rosenberger offers a wide range of specialist tools and accessories including those for crimping and handling crimp inserts, as well as torque wrenches and various extraction tools and accessories.

Rosenberger provides customized solutions – cost-optimized and timely – from the initial idea right through to volume production.

Download catalogs, flyers and other latest product information as well as measurement data protocols for your products.

Read the latest news from Rosenberger and check out our trade fair appearances. If you want to receive the latest news by email, register for our newsletter.

We have the pragmatic power of innovation that is needed to keep tackling new challenges and developing solutions that help our customers move forward.

A Tittmoning fitters workshop turns into a worldwide concern that is technically one of the most innovative as well as one of the largest and most reputable in its sector.

More than 15,000 employees work for the Rosenberger Group worldwide every day - 3,300 of them at our headquarters in Fridolfing. With their commitment and competence they are responsible for the success and the future of the company. You too can become an indispensable part of our team!

In our job portal you will find all current vacancies for the Rosenberg headquarters in Fridolfing, Germany.

Our connectivity experts will be happy to give you further information on our solutions. Get in contact with us to find the best connection solution for your application.

Are you a highly motivated young professional seeking to ensure exceptional product quality?

Rosenberger is currently looking for individuals like you to join our team as Quality Managers. In this role, you will have the opportunity to make a significant impact on our organization's success by ensuring the quality of our innovative products with other teams in the company. We value hands-on support, analytical abilities, organizational skills, attention to detail, and a strong commitment to continuous improvement.

Rosenberger's Quality Management Department comprises among others

Automotive Core Tools (APQP, PPAP, FMEA, SPC, MSA), Six Sigma, 5Why, Ishikawa and 8D are familiar terms to you and you have great communication skills? Apply your knowledge and skills by joining our team in quality management at Rosenberger. We are looking forward to your application!

Find out what a Quality Manager at Rosenberger does in our video.

"As a QM Service Engineer I combine technology and management in an optimal way. Thanks to my interdisciplinary role I work in cross-departmentally structured teams - with Product Managers, Design Engineers and Process Developers which makes my work exciting and varied."

"I coordinate interdisciplinary teams to find solutions to problems, moderate internal and external meetings and conduct process reviews at suppliers' premises. I use quality methods to analyze problems and eliminate errors sustainably."

"Being the link between different internal departments and the communication with both customers and suppliers brings exciting and varied tasks."

"The induction phase is well organized and begins with an extensive introductory week during which you get to know the company and make initial contacts with other new employees."

"The interaction with colleagues and dealing with different technologies within the framework of quality management."

"When it comes to root cause analysis and problem solving not only is working to 'Scheme F' required but also creativity and innovation.”

"You can always rely on the helpfulness and spontaneity of colleagues throughout the company."

"It fills me with pride seeing a project that you have accompanied from the concept idea to series production being successfully completed. Then I realize that the efforts and endeavors have been worthwhile."

"It requires technical understanding with the knowledge of electrical and mechanical requirements as well as a friendly and determined communication with suppliers, customers and colleagues."

"We are a young, dynamic team with an international setup. Regular events such as bowling or soccer golf strengthen the team spirit even more and are one of the main reasons for the good atmosphere."

Stephan Bichlmaier

Markus Schönau

Three weeks of Onboarding

Get to know Rosenberger

Bootcamp for Project Teams

Attractive Salary

Capital-forming payments

Bonuses

Employee discounts for various products and services

Health

Company's gym

Free sport courses, e.g. yoga & functional training

Healthy meals at the company's restaurant

Exceptional team spirit

Great colleagues

First name terms, regardless of hierarchical level

Lots of potential to grow

Quality-relevant guidelines and processes are in place to comply with Rosenberger’s zero-defect strategy. These include, among other things, the performance of internal audits, education and qualification of employees.

In 2002 Rosenberger became the first manufacturer of coaxial connectors to be certified according to ISO/TS 16949.

The company has the following quality and environmental certificates: