Rosenberger Provides Customized Solutions – Cost-optimized and Timely – From the Initial Idea Right Through to Volume Production.

Idea/Concept

Every Solution Starts with an Idea.

The development of new ideas and their development towards implementable solutions that add value is part of Rosenberger's customer promise. Based on your technical and commercial specifications, an overall concept for the realization of your product is created. In addition to the fulfillment of electrical and mechanical requirements, Rosenberger also selects the suitable technologies to transform your idea to reality.

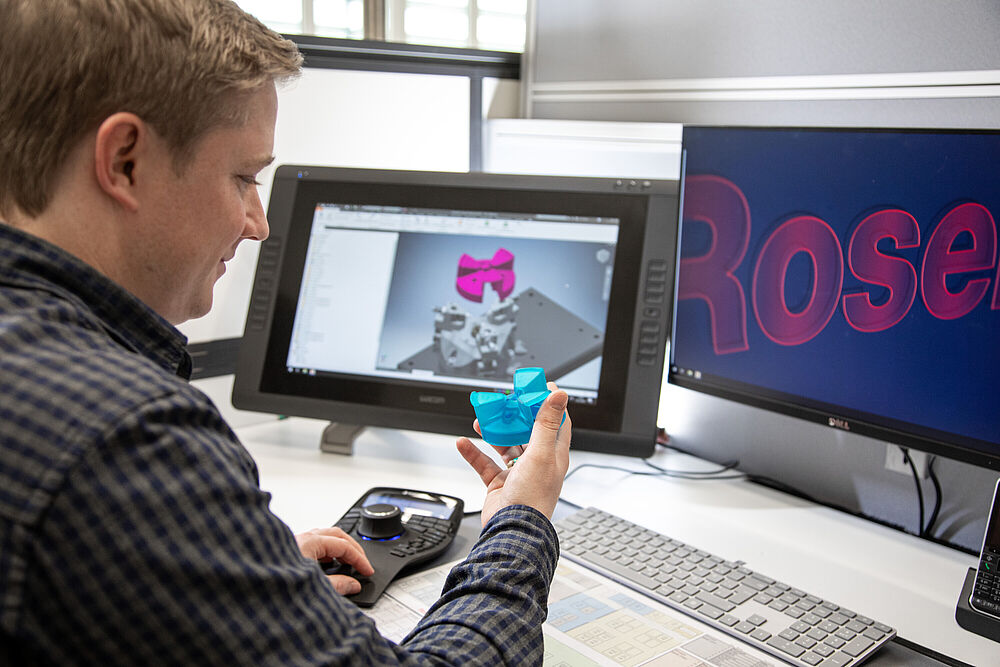

Design/Part Selection

Rosenberger selects all electrical and mechanical components according to relevancy and function and ensures the derivability of the components over the planned project duration.

Modern design and simulation tools reduce the number of design cycles and accelerates the development time.

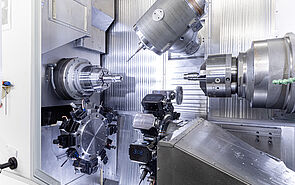

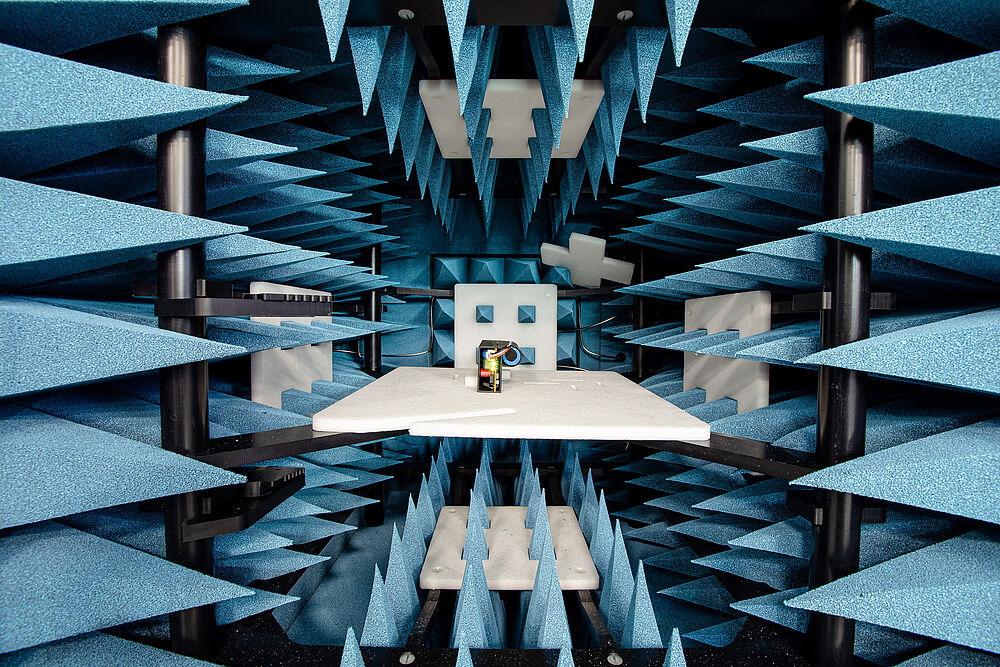

Mechanical Construction

Through the integration of electrical and mechanical development, the design can be verified prior to prototyping.

All design, material, environmental and compliance requirements are determined at this stage.