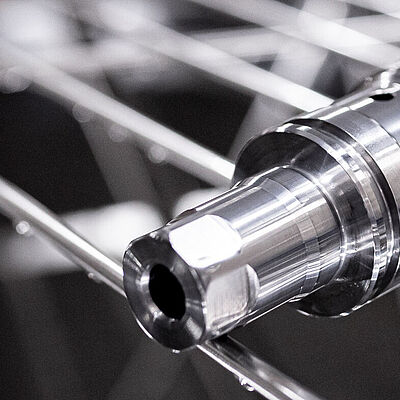

Design Verification and Reliability Testing

Rosenberger Always Delivers when it Comes to Products of the Highest Quality and Maximum Precision

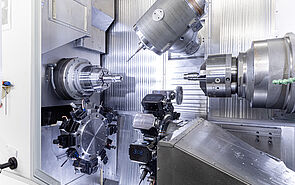

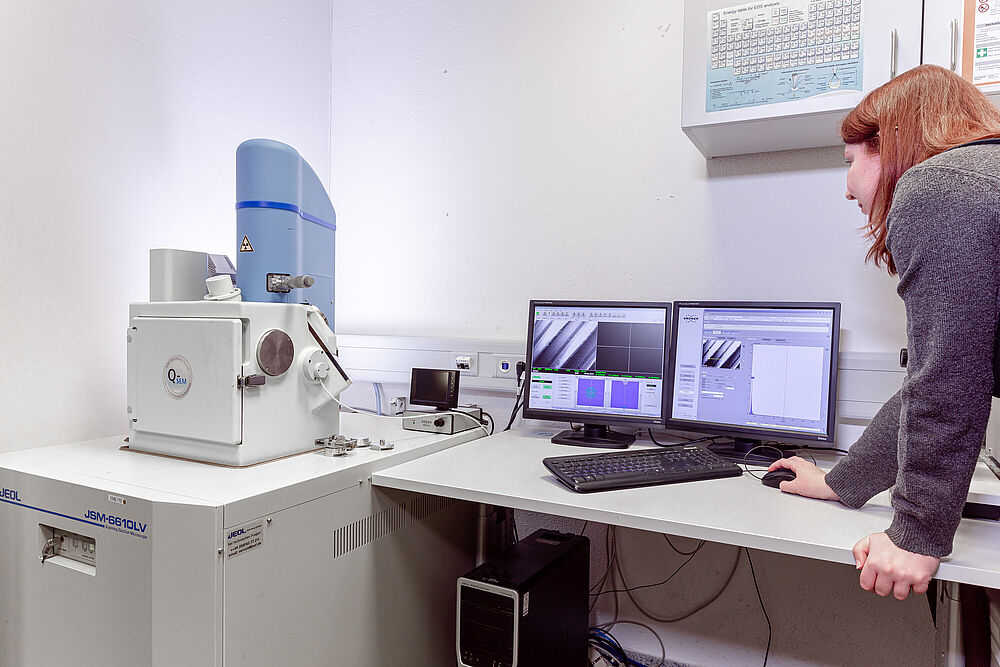

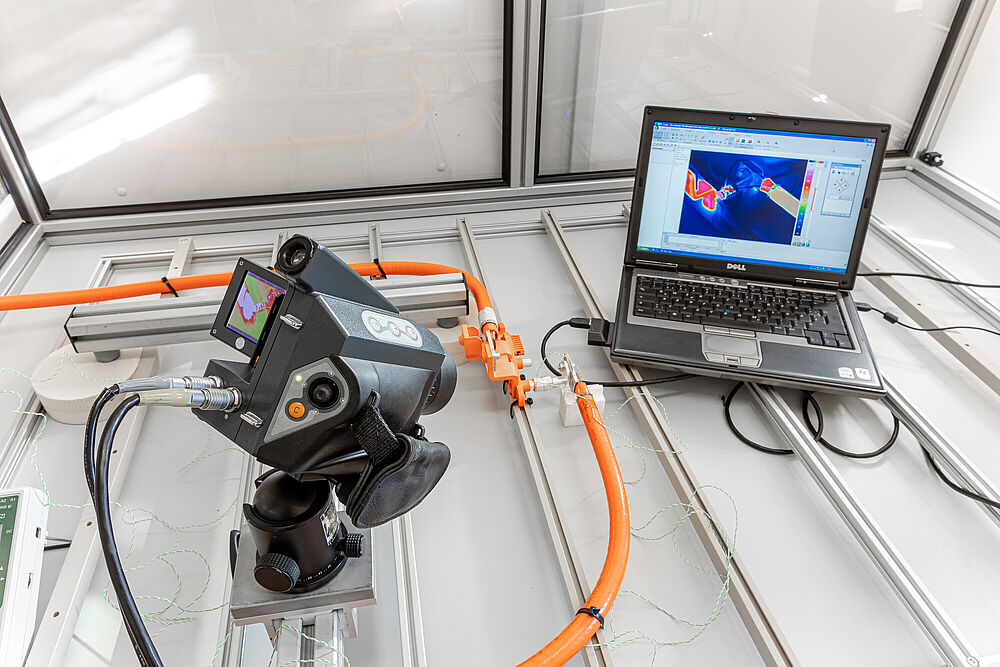

The ability to achieve such a high standard of product excellence is down to extensive testing and validation which is performed at the company’s Test Laboratory. Here simulation techniques carried out beforehand in Research and Development are put into practice enabling highly effective validation of the properties functionality and design of all products.

The Test Laboratory’s state-of-the-art equipment and highly trained personnel are able to carry out environmental simulations, mechanical and electrical tests as well as optical analyses. The testing process is innovative and solution-oriented, delivering fast decisions based on valid results and extensive documentation.