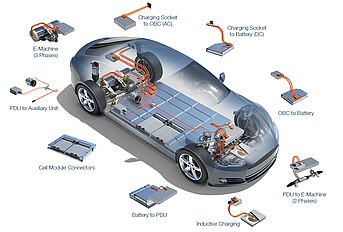

The future of our locomotion lies in electric and hybrid cars. Increasingly, the internal combustion engine is being replaced by technological progress which in turn has called for major innovation in the field of connector technology, for both hybrid and electric vehicles. At the same time, efficient and environmentally-friendly production methods are a top priority when it comes to corporate social responsibility (CSR).

Rosenberger products stand for precision, durability and quality at the highest level. The company has considerable expertise in the automotive sector from two decades of designing and producing both customized solutions and standard products.