Whether Large or Small Quantities, the Rosenberger Group Manufactures High-Quality Piece Parts with Maximum Precision; even at High Complexity for All Business Areas

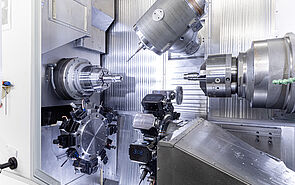

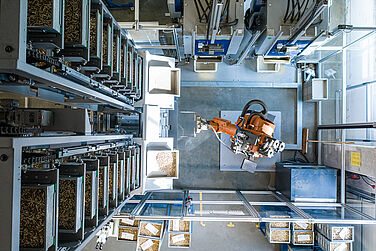

Shaping is a mechanical process by which parts are produced in the desired shape. The resultant excess material is removed as chips. In addition to the use of innovative production plants Rosenberger sets quality standards throughout the entire production process: maintenance and servicing of machines is carried out internally. Furthermore, the rigorous raw material procurement system and high degree of automation in the finishing of produced parts minimizes pre- and post-processing. The company's custom solution guarantees a short turnaround from product development to series production, including extensive quality testing at all stages of production.