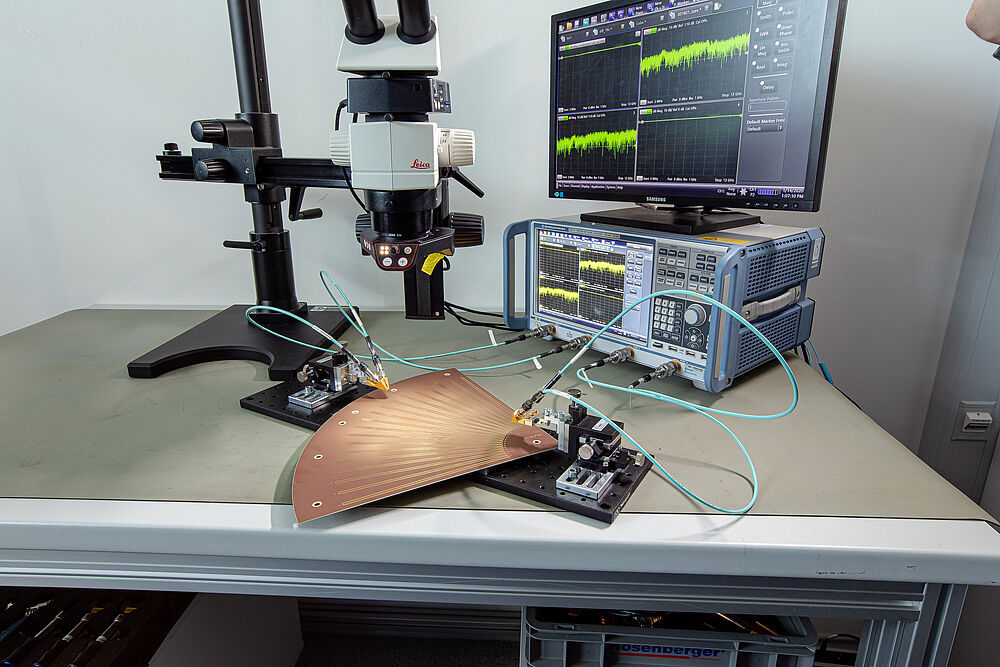

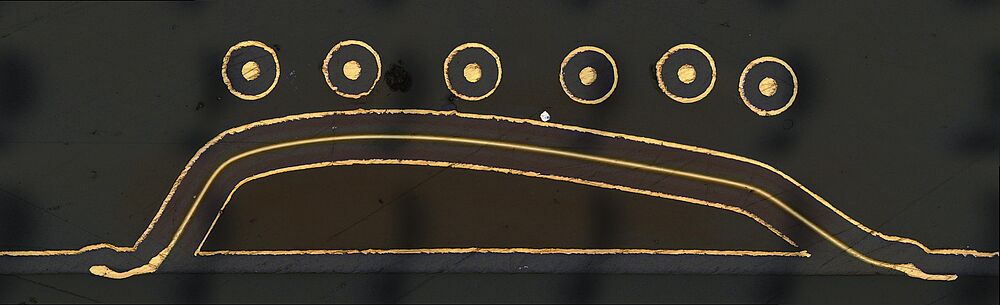

In Addition to Fixed Systems Pioneering Technologies such as the Internet of Things (IoT) and Autonomous Driving Require Very Small and Highly Flexible PCBs

Because of the increasing level of miniaturization and the growing cost considerations regarding connectors and cables, the analysis and prediction of mechanical properties of Rosenberger products has become increasingly important.

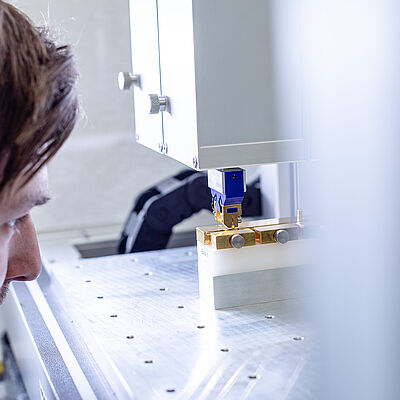

To precisely satisfy these requirements the company uses its own in-house simulation capabilities and test methods.