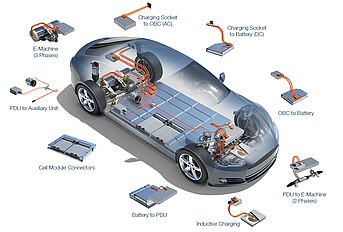

Die automobile Zukunft liegt zunehmend in Elektro- und Hybrid-Autos. Verbrennungsmotoren werden kontinuierlich durch technische Neuerungen ersetzt – das erfordert für Fahrzeuge mit Hybrid- und Elektromotoren eine ebenso fortlaufende Innovation im Bereich Steckverbindertechnologie. Gleichzeitig führen effiziente und umweltfreundliche Produktionsmethoden den gesellschaftlichen Anforderungskatalog an.

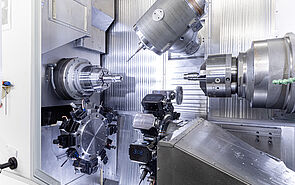

Rosenberger-Produkte stehen für Präzision, Langlebigkeit und Qualität auf höchstem Niveau. Im Bereich Automotive blickt das Unternehmen auf eine langjährige Expertise, denn Rosenberger war maßgeblich an der Entwicklung von Steckverbindungen für die Automobil-Branche beteiligt und setzt damit Innovationsstandards.